Expert Environmental Impact Assessment and clearance services, ensuring your projects comply with India’s environmental regulations while promoting responsible growth.

Pesticides Industry

Synthetic Organic Chemicals Industry

Ports, Harbours, Breakwaters & Dredging

Common Effluent Treatment Plants (CETPs)

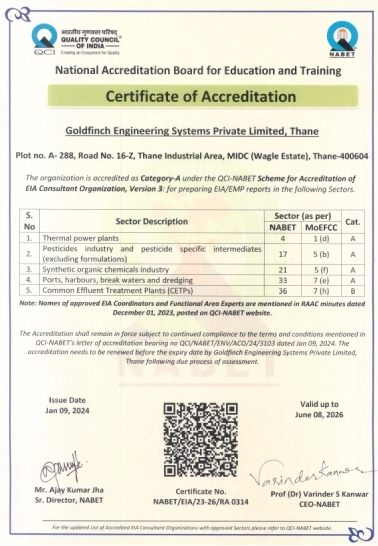

These accreditations mean our organization meets strict national standards for technical competence and quality control. We have approved EIA Coordinators for each functional area relevant to these sectors, ensuring we understand industry-specific regulations and can efficiently manage EIA studies and clearance processes tailored to your sector.

Securing an Environmental Clearance (EC) involves a structured multi-step procedure. Goldfinch guides clients through each stage to ensure timely compliance and approval.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Our strength lies in a versatile, multi-disciplinary team of specialists with deep experience in environmental regulations and technical assessments. We employ: chemical and environmental engineers for process and pollution control expertise; air quality and water resources experts for dispersion modeling and hydrology; ecology and biodiversity biologists for habitat surveys; risk and safety analysts for hazard studies; and socio-economic consultants for community impact and resettlement planning.

Complete EC proposal preparation and submission to MoEF&CC or SEAC/SEIAA, including scoping, ToR compliance, and follow-up till clearance.

Full-scale EIA studies with baseline data collection, impact analysis, mitigation planning, and Environmental Management Plans.

CRZ demarcation and clearance coordination with CZMA, ensuring project design complies with CRZ notification rules.

Industry consent applications to State/Central Pollution Control Boards under Water and Air Acts, including compliance checks.

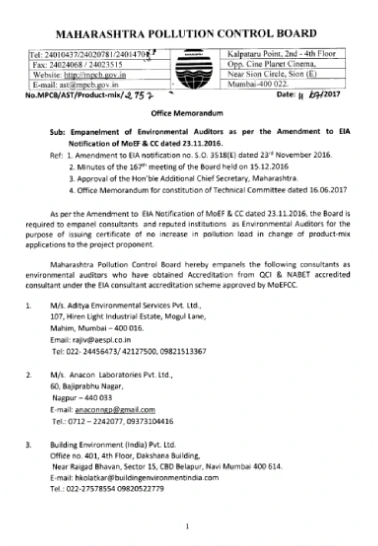

Amendment applications for product mix changes in chemical/pesticide units, with No Increase in Pollution Load certificates.

Advanced modeling (AERMOD) to simulate pollutant dispersion, identify impact zones, and design effective controls.

End-to-End Service

No. Starting construction, production, or land development without prior EC is a violation. This can lead to:

Violations can lead to:

7-8 word description about what they do

Real-world success stories demonstrating our expertise

Treated effluent met regulatory discharge limits for organics and pesticide residues; plant compliance restored and operating costs reduced via optimized aeration/nutrient control and lower chemical dosing

EIA/EMP provided actionable mitigation and monitoring; regulatory clearance secured and construction proceeded with minimized ecological disturbance and clear compliance pathways

CETP achieved steady compliance across key parameters, reduced sludge and energy consumption, and improved resilience to load fluctuations

Ready to Start Your Project?

Address

Plot A – 288, Road No. 16 – Z,

Opp. Agricultural Office Bus-stop, MIDC,

Wagle Estate, Thane (W) – 400604