Cost-effective, customized wastewater treatment systems engineered for pharma, chemicals, food processing, and diverse industrial applications.

Trusted Since 1983 | 40+ Years of Wastewater Expertise

Our Methodology

Reliable process equipment, from pressure vessels to skid-mounted plants.

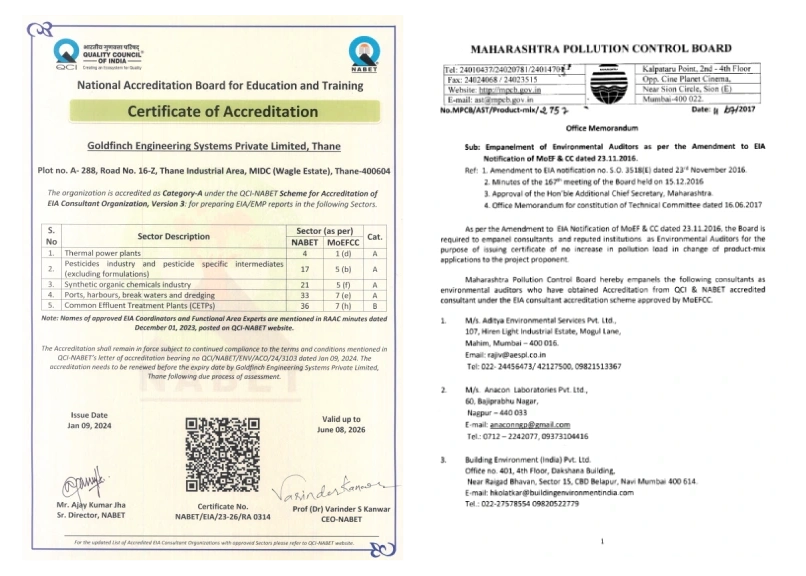

Certifications & Compliance

We design everything from small (tens of KLD) to very large industrial systems. Goldfinch has implemented package ETPs for single-unit facilities as well as huge systems for industrial estates. In fact, we have operated ETPs and CETPs up to 16,000 m³/day on behalf of clients. Your plant’s capacity needs will be met with a scaled solution.

We begin with thorough analysis in our NABL-accredited lab. Bench-scale tests (e.g. aerobic oxidation) are run to determine the optimal process conditions. The ETP is then sized (reactor volume, oxygenation, detention time) to achieve target removal (typically BOD <30 mg/L, COD and TSS per norms). Goldfinch’s design follows CPCB and MoEF guidelines, and we hold ISO 9001:2015 and OHSAS 18001 certifications for quality and safety.

Ready to Start Your Project?

Address

Plot A – 288, Road No. 16 – Z,

Opp. Agricultural Office Bus-stop, MIDC,

Wagle Estate, Thane (W) – 400604